Driving sustainable value creation remains at the core of our efforts at BALCO. It empowers us to initiate sustainable manufacturing processes across our plants, upgrade facilities and consistently adopt cutting-edge technology to minimise our environmental footprint.

Our integrated approach enables us to enhance operational efficiency and optimise costs, thereby allowing us to retain a competitive edge in the global market.

BALCO owns bauxite and coal mines, power plants, refineries, and smelters. Since its inception, the Company has successfully developed 5,80,000 TPA of smelting capacity. In addition, the fabrication facility has been expanded to include three Properzi rod mills for EC rods & one HindUdyog for Alloy rods, three Ingot casting machines (two EC & one for PFA), integrated hot and cold rolling mills and three power plants of 270 MW + 540 MW + 1200 MW capacity.

Improvement in coal handling plant crushing capacity

Certified for manufacturing and supply of calcined alumina, aluminium ingots/billets, aluminium rods and aluminium rolled products.

We have achieved a remarkable milestone in our supply chain operations by migrating from Free on Board (FOB) to Cost, Insurance and Freight (CIF) system. This has significantly helped to bring down our logistical expenditure and optimised the overall production cost.

We have also successfully reduced the frequency of demurrage, detention and dead freight (for commodities like Alumina, CP Coke, CT Pitch ALF3, Coal, etc.) in our supply chain operations to drive a significant impact on our cost of production.

BALCO is the only company in India to receive approval for simultaneous export and import. It has bolstered the power business and has enabled the Company to incur recurring benefits. Our Chotia coal mine, with a capacity of 1MTPA, located in Hasdeo Arand coal field of Chhattisgarh, has restarted operations and is expected to ensure sustainable coal sourcing in the days ahead.

For an aluminium manufacturing company, optimum utilisation of ash is significantly beneficial. At BALCO, we have successfully achieved the highest ever ash utilisation mark of over 174%. It has not only enhanced cost effectivity, but also reduced waste generation, contributed towards the conservation of natural resources and decelerated greenhouse gas emissions from power plants.

Ash utilisation

BALCO emphasises the importance catering to future demand of a structured approach to asset optimization. We aim to enhance asset life, increase throughput and reliability, and achieve these objectives in a cost-effective and sustainable manner. This policy applies to all individuals responsible for operating and maintaining BALCO’s assets.

To achieve these goals, we implement a systematic approach to assess equipment performance and evaluate the asset management of different Strategic Business Units (SBU). This includes conducting criticality analysis, condition appraisals, and developing refurbishment plans.

We have established a comprehensive framework for various maintenance activities, such as operations and plant maintenance, equipment maintenance, utility operations and maintenance, building and ground maintenance, facilities protection and security, and safety and environmental compliance.

Our sustainability strategy is focused on evolving production processes to become more efficient with increased effort on conserving the resources as much as possible. We are taking active initiative in our raw material conservation through the process of recycling and re-usage. The used anode butt from our production process is again utilised in the production of fresh anodes. We also recycle cast iron in anode rodding. Through these steps, it has brought an overall reduction in fresh procurement of pig iron and Calcined Petroleum Coke.

At BALCO, we have digitised operations to enhance efficiency and production capability. We have adopted artificial intelligence-based Auto HSSE (Health, Safety, Security and Environment) monitoring system, to ensure safety and security at the workplace and lower risks of accidents at manufacturing plants. The system also enables compliance to regulatory mechanisms and allows us to sustain HSSE standards. These efforts not only contribute towards long-term sustainability but, also support our endeavours to ensure cost-efficiency.

We have also adopted digital methods to track lube oil consumption and maintain optimum oil levels. The advanced technology helps to identify inefficient machinery and equipment that consumes more oil and allows us to take timely action. Moreover, it also ensures recovery of used oil and optimises oil consumption, thereby bringing down costs significantly. Accurate data related to oil usage and waste disposal is also obtained through this system.

Planning of coal materialisation is also eased with the use of advanced technology. It helps to track the supply of coal from mining sources along with its transportation and storage. It also ensures proper loading and unloading of coal. It, therefore, facilitates better resource management through real-time monitoring and quick identification and redressal of various issues.

To reduce downtimes and ensure optimum productivity of machines, we have undertaken efforts to regularly overhaul our units and machinery to prevent breakdowns, increase the lifespan of units and maintain the quality of products. This also allows us to repair or replace parts at the earliest, an effort that proves to be quite cost effective in the long run.

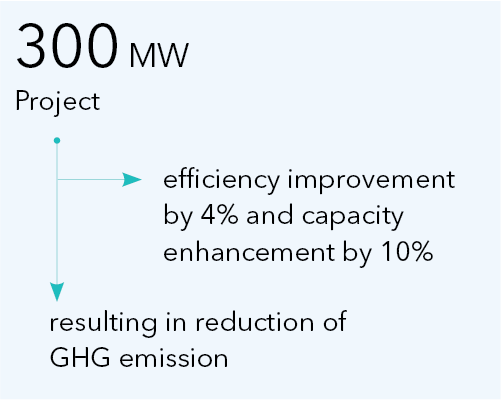

To be more cost efficient, the process needs to be more energy efficient. Energy efficiency depends mainly on the technology used and relining materials being used. In a electrolytic cell, energy consumption can be reduced by reduction of voltage drop & increasing the pot life.

We have our in-house dross processing mechanism to process the byproduct generated from aluminum melting.

Capacity: 10,000 MTPA

100% processing with

35% metal recovery

We have implemented Kaizen across our manufacturing processes. Through this, we are able to identify the source of the problems and enhance productivity. Following are the key improvements achieved through the implementation of kaizen-

Savings per month

Savings per month

Savings

Savings

Savings

According to a study conducted by BCG, the demand for aluminium in the Indian subcontinent is expected to grow by three times, to reach 12-13MTPA by 2030. Demand is primarily expected to arise from packaging, automobile, machinery, manufacturing and infrastructure.

Taking into consideration the growing demand, we have planned to expand our aluminium smelting capacity from 0.58 million TPA to 1 million TPA. The comprehensive expansion plan also takes into consideration the requirement for essential resources such as water and power. We already possess a captive power plant, which is set to undergo further capacity expansion. As a result, additional permissions for water and power supply will not be necessary, enabling a smoother execution of the expansion project.

The new manufacturing plant is equipped with world-class facilities for:

Along with its smelter expansion, BALCO strives to expand its finished goods production capacity from 51KTPA to 180KPTA. Billet production capacity is also expected to increase to 420KTPA and primary foundry alloy facility will enhance output by 90KTPA.

BALCO has purchased over 500 MU (megawatt-hours) of renewable energy (RE) in FY 2023 and aims to further procure sustainable RE power for its smelting operation. This will significantly lower greenhouse gas emissions in comparison to traditional fuel-based power generation. It is also a step towards improving the air quality while reducing the risk of global warming.

Additionally, we are implementing biomass firing in our facilities. This carbon-neutral energy is expected to significantly reduce our environmental footprint. By transitioning towards sustainable energy usage within our operations, we strive to improve our contribution towards a cleaner and better tomorrow.

At BALCO, we lay great emphasis on producing the finest quality products. Our state-of-the-art laboratory adheres to various quality standards and relies on a quality-first approach. We also comply with ESG policies and strive to ensure sustainability during the procurement process. BALCO has strengthened its focus on upgrading and acquiring new testing equipments and instruments to improve the accuracy, efficiency and reliability of lab operations. We also developed robust quality culture by implementing Quality Management system such as ISO 9001 to streamline the process and improve the traceability of test reports.

Certified for quality management system

In order to maintain an integrated supply chain, we engage in robust planning of B2B sales processes to create an optimum balance between demand and supply. Also, we strongly coordinate with the transportation team to ensure timely delivery of goods. BALCO is consistently working to improve delivery standards and utilises bestin- class packaging to ensure zero consumer complaint.

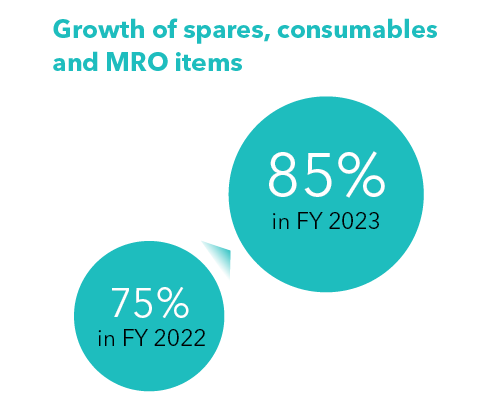

BALCO has an effective and automated inventory management system incorporating the following:

At BALCO, we remain committed to foster a sustainable tomorrow. Accordingly, we have invested in energy efficient equipment that helps to conserve energy and minimise our carbon footprint. We have adopted video analytics, artificial intelligence and machine learning based tools to become an environmentally responsible organisation and achieve our net zero target. Also, we strive to minimise waste generation from our production process through optimum utilisation of raw materials and use of products that can be recycled. We are also encouraging our supply chain partners to adopt green initiatives. Moreover, to reduce the use of paper, we continue to adopt digital channels of communication.

We are minimising carbon emissions across the units by implementing innovative measures. We are using FTP with lower specific power consumption and also enhanced our pot lining life which has significantly resulted in reduction of carbon footprint.

Reduction in specific power consumption from

Specific CO2 emission reduction

Through enhancement of pot lining life from 1800 days to 2190 days