At BALCO, we are cognizant of the impact of our business on the environment. We are conscious of our ecological footprint and are working relentlessly to optimise the use of the natural resources, restrict emissions and encourage circular economy.

We have scaled up our efforts to reduce our carbon footprint by employing renewable energy in our operations, using water responsibly, effectively disposing of waste, and conserving biodiversity to create value sustainably.

Certified

Certified

Certified

As a Vedanta company, we have are committed to adapt and mitigate climate change.

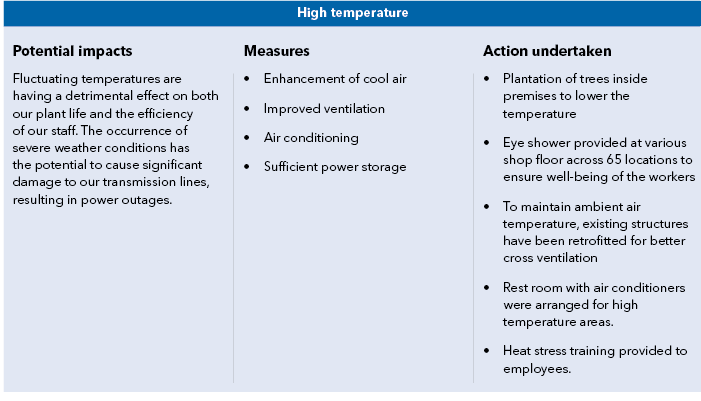

To combat climate change, we have moved away from traditional energy sources by using renewable energy in our operations. In FY2023, 546.29 MU of renewable energy was procured and we intend to grow our renewable energy procurement till 2030. This will significantly reduce our GHG emission.

We have also replaced heavy furnace oil in power plants and metal production regions with more ecofriendly fuels. We are also integrating biomass co-firing with coal, which decreases coal usage, thereby reducing greenhouse gas emissions.

We are under the trial phase to use bio-diesel in our production process to run our utility vehicles. The mobility of two-wheelers within the premises is also now limited, reducing Scope 3 emissions significantly.

Our organisation has taken a significant initiative to combat emissions by committing to decarbonise 100% of our light motor vehicles by 2030. As part of this commitment, we are implementing a radical change to our Company Car Policy, which will impact all employees. The new policy includes higher slabs for purchasing conventional vehicles and Vehicle Maintenance Allowance (VMA), along with a market-leading Electric Vehicle (EV) element.

By implementing these changes, we aim to motivate all our employees to embrace sustainable transportation and integrate sustainability into their daily commutes.

The Perform Achieve and Trade (PAT) mechanism is a way to speed up and encourage energy efficiency in the market. It focuses on energy-intensive industries and large facilities. Under PAT, energy savings are certified and can be traded as Energy Saving Certificates (ESCERTS), making it more cost-effective to improve energy efficiency. As a Vedanta company, we have are committed to adapt and mitigate climate change.

We have implemented innovative pre-bake equipment to minimise fugitive and stack emissions from our aluminium smelter in order to decrease air pollution. Dust extraction and dust suppression systems have been installed to help with this.

As an important lever of the decarbonisation process, we plan to adopt Internal Carbon Price mechanism from FY24 onwards for all business’ operations and all the major upcoming expansion projects based on the criteria defined in this SOP. We want to implement shadow pricing during the evaluation of new projects to drive low carbon project choices; thereby ensuring carbon risks are considered during the project evaluation stage.

We have conducted gate-to-gate life cycle assessment as of now. Later we are also planning to conduct cradle to gate analysis. The objective of the LCA is to provide life cycle based environmental information based on gate-to-gate system boundary for aluminium production to identify environmental hot-spots and develop strategic environmental decision-making focusing on climate change. The LCA is carried out in accordance with the ISO standards on LCA: ISO 14040 (2006) and ISO 14044 (2006).

We are highly committed to creating an effecient waste management system since the aluminium and power sectors create hazardous waste throughout the manufacturing process that can cause serious environmental harm if not managed properly and in accordance with government rules. As a result, we manage our waste through proper waste storage, transportation and disposal.

Manifest forms are created with respect to each vehicle for appropriate transportation of hazardous waste to licenced recyclers or re-processors, ensuring total security. Waste is disposed of responsibly by incineration in designated sites such as licenced guarded landfills and closed sheds. The graphitisation technique reduces SPL generation, a hazardous waste, while also increasing the pot life utilised in aluminium manufacturing.

Aluminium Dross processing and metal recover through an unique technology for sustainable use of a hazaradous waste is example of a Circular Economy adopted through partnering with Runaya.

Our non-hazardous wastes consist of metal scraps, PVC scraps and plastic scraps which are melted and reprocessed to ensure reuse along with the wooden waste. The CP coke wastes are used to make electrode paste. This ascertains that 100% of our non-hazardous wastes are recycled within the plant to ensure sustainability of the environment.

We have implemented a High Concentration Slurry Disposal (HCSD) disposal system. Treated waste water is used to create ash slurry, which is then disposed of in ash dykes. More than 100% of the fly ash is used in various applications such as road building, cement industries, brick making and so on.

Optimum utilisation of fly ash is ensured along with ensuring lower ash content in coal.

We conduct regular waste management audits to ensure and monitor the effectiveness of our waste utilisation.

BALCO has an advanced Solid Liquid Resource Management Centre (SLRM) at the forefront of waste management technology. This centre is fully equipped to handle approximately 5 tonnes of mixed municipal waste, demonstrating its impressive capacity.

The SLRM centre comprises various essential components, including a segregation area, a Composting System comprising a Composter and Pit system, a Plastic and paper recycling machine. By incorporating cutting-edge practices and adopting a wellthought- out design, the SLRM centre is an end-to-end waste disposal solution. It effectively manages the entire waste lifecycle, from initial collection to final treatment and disposal. By minimising waste generation within its premises, BALCO significantly reduces its environmental impact and sets a commendable example for sustainable waste management.

The entire waste management process at the SLRM centre is characterised by a well-defined workflow, from waste collection and sorting to processing and treatment. This systematic approach ensures that each type of waste is managed appropriately, maximising the potential for resource recovery and minimising the overall environmental impact.

From FY 2023 onwards, BALCO has banned all single-use plastic bottles and plates within the plant premises. It has been replaced with glass bottles and paper plates.

BALCO is actively trying to reduce water usage and recycle waste water to contribute to its larger mission of water conservation. Our plants are built in such a way that no liquid waste is discharged into water bodies from our plants.

Of fresh water consumption was reduced in FY 2023

Moreover, water utilised for industrial and domestic purposes is recycled. The wastewater is collected through covered drains and pipelines and then treated at ETP, a RO-based system. The treated water is then reused for horticulture and sprinkling.

of water has been recycled in FY 2023

To reduce water pollution, reverse osmosis is done to treat the wastewater prior to recycling it in the raw water reservoir. We also have our sewage treatment plant that treats domestic sewage from our plants. The treated water is used in greenbelt development and dust suppression.

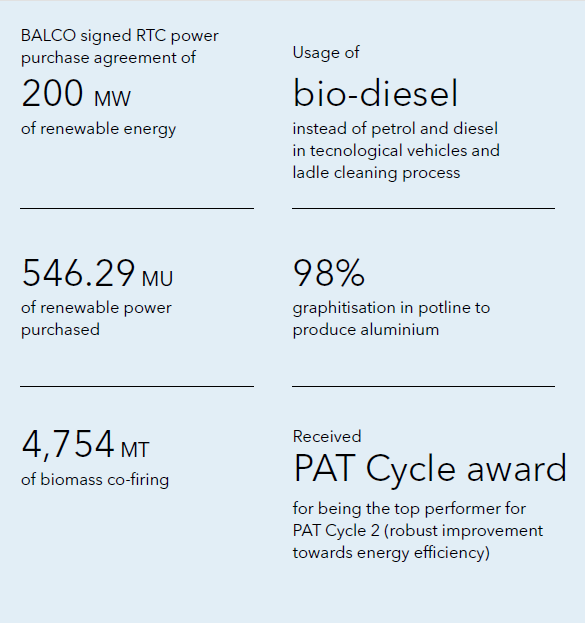

We are taking steps to decrease our energy use across all our businesses to reduce our carbon impact. We are implementing numerous approaches and procedures that are yielding significant results and assisting us in being more energy efficient. We are primarily sourcing and inclining towards renewable energy usage, with intentions to expand our renewable energy procurement rate in the future.

During FY 2023, BALCO has taken active measures to optimise its energy consumption in its Smelter operation as follows:

It is our responsibility to use natural and precious resources optimally for the benefit of future generations. Despite being into manufacturing, we are committed to lowering our carbon footprint through various measures. Through our sapling plantation project, we are contributing to biodiversity conservation. We successfully restored and stabilised ash dykes by planting over 1 lakh trees.

Saplings planted in FY 2023, making a total of more than 8 lakh saplings

At BALCO, we believe in promoting sustainability across the organization to align ourselves to global targets. Towards developing a culture of close adherence to environmentally aligned practices, we are encouraging our workforce to proactively adopt an eco-friendly lifestyle. In sync with this, we have introduced various initiatives in the past quarter like carpooling among employees, organizing regular awareness sessions for the schools in its vicinity and switching to green consumerism.

Under the above notion, BALCO has also launched a novel initiative ‘Making Birthdays Greener’, under which employees are invited to plant a fruit sapling on the eve of their birthday. The objective behind this initiative is to demonstrate ways to make important celebrations more environmentally friendly. The resulting orchard born out of the sapling planting initiative will also serve as an inspiration for future generations to do their own bit for the planet. 86

BALCO has not violated the environmental regulatory policies in the last 4 years and is focused to sincerely contribute to the protection of the natural resources in the upcoming years as well.

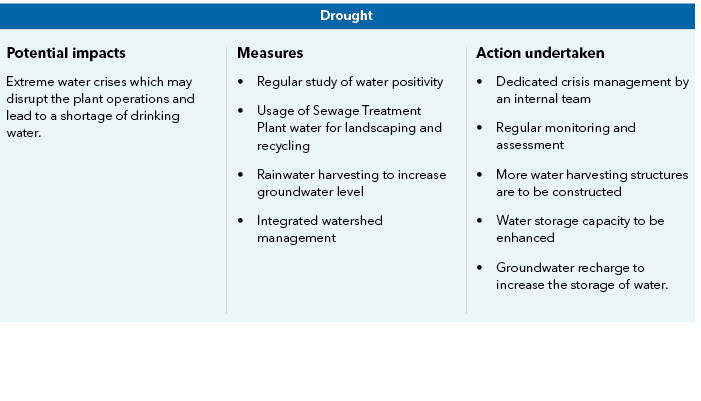

We have conducted climate change risk assessment for our sites. This study was conducted for BALCO between the time period 2020- 2060, by estimating the degree, and financial impact of those risks especially physical and transition risks.

BALCO has employed scenario analysis techniques, utilising locationspecific data and tools like the World Bank Climate Change Knowledge Portal (CCKP), World Resource Institute (WRI), National Oceanic and Atmospheric Administration (NOAA), and International Best Track Archive for Climate Stewardship (IBTrACS). These resources enable us to examine historical trends and project future climate-related risks in terms of extreme weather events such as droughts, floods and cyclones, as well as long-term physical changes like rising temperatures and sea levels and alterations in precipitation levels. By focusing on Representative Concentration Pathways (RCP), particularly RCP 4.5 and RCP 8.5, we aim to comprehend the potential effects of climate change on temperature and rainfall patterns across our operational units.

Industries with high greenhouse gas (GHG) emissions are likely to face various transition risks as the global momentum for decarbonisation intensifies. These risks encompass policy and regulatory changes, legal implications, technological advancements, market shifts and reputational challenges. To proactively address these risks and adapt to evolving market trends and policies, we conducted a transition risk scenario analysis aligned with the Network for Greening the Financial System (NGFS) framework.

Our analysis was based on the International Energy Agency’s (IEA) Beyond 2 Degrees Celsius (B2DS) and Net Zero 2050 scenarios. These scenarios provided the foundation for developing appropriate strategies in the transition towards a low-carbon economy. We utilised the NGFS framework, which consists of five scenarios-

To generate the transition pathways for these NGFS scenarios, we employed a well-established integrated assessment model. These pathways were created by considering key design choices such as long-term temperature targets, net-zero targets, short-term policy measures, overall policy coordination and technology availability. By incorporating these factors into our analysis, we aimed to provide comprehensive insights into the potential risks and opportunities associated with the transition towards a low-carbon economy.